The big thing lately has been working on the elevators. Having been frustrated with my hot wiring of the elevators, I ordered a set of elevator cores from Eureka CNC. Real nice.

This photo shows the foam blocks that the cores were cut from.

The aluminium torque tube being installed with wet micro, a mix of epoxy and glass microballoons. The torque serves as the backbone for the elevators.

The elevators have been glassed on one side. Looking pretty good.

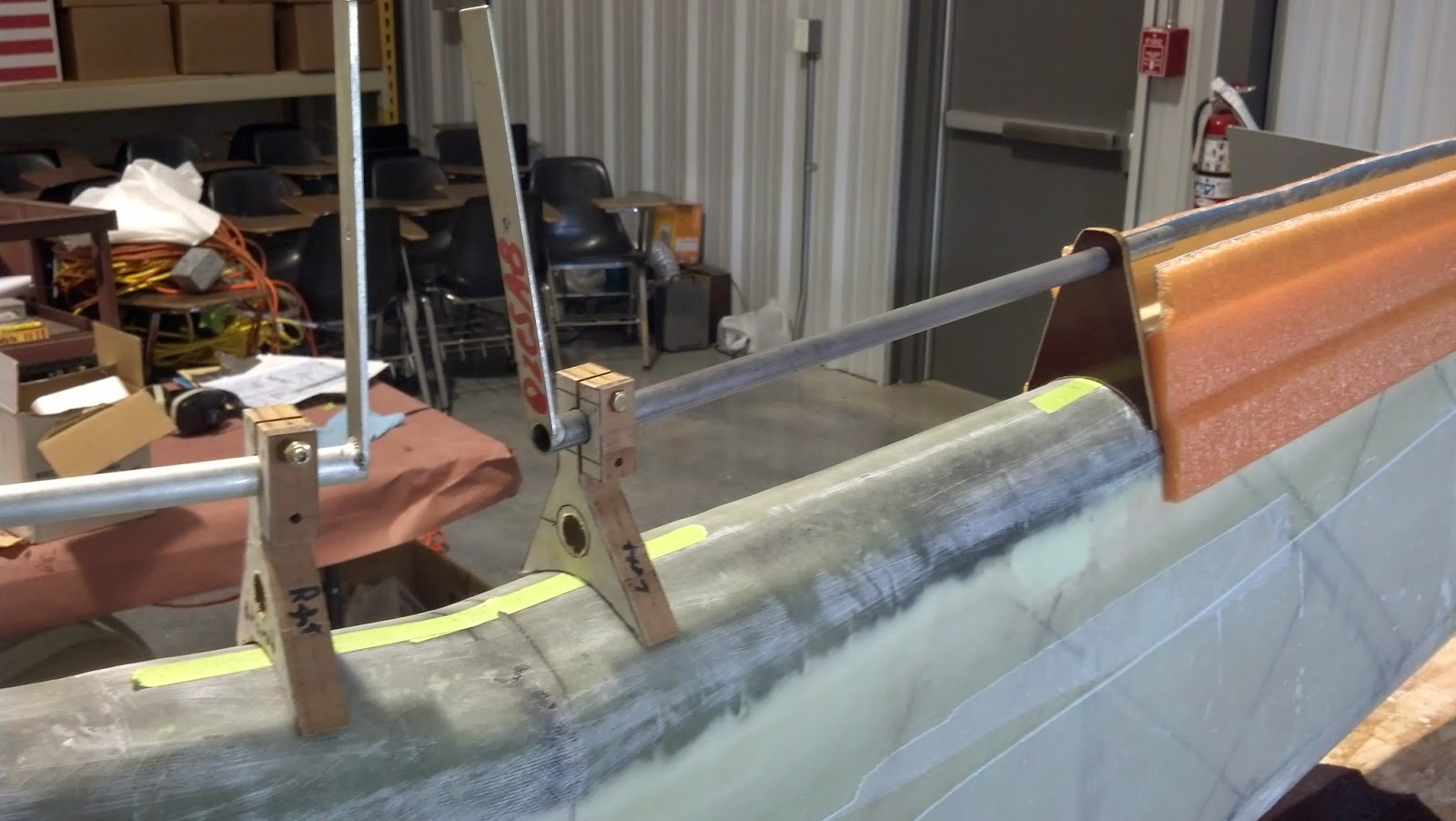

Fast forward a bit. The elevators are glassed on the bottom side first. After curing for a couple of days, the top side is glassed. To make sure it all remains nice and straight, we lightly clamped the trailing edge to a very flat table.

Canard jigged in preparation for installing the elevators and attachments.

The next order of business is to do a lot of fitting. The orange slot cores are positioned and roughly trimmed to length. The phenolic elevator hinge bearings are cut and positioned, then I try and figure how it's all going to align properly.

A major gripe I had about the Quickie Aircraft Company (R.I.P.) plans, is they hardly ever used dimensions, only templates. Say you wanted to know how far the elevator torque tube should stand off from the canard spar. All we can do is take our best guess, hence the tag EXPERIMENTAL.

Those vertical arms will eventually connect to the aircraft's control stick.

It's starting to look like a real canard (front wing). I have still several small aluminium parts to make up and fit. With a bit of perseverance, I should have all this rigged up within a week or so. Ha ha.